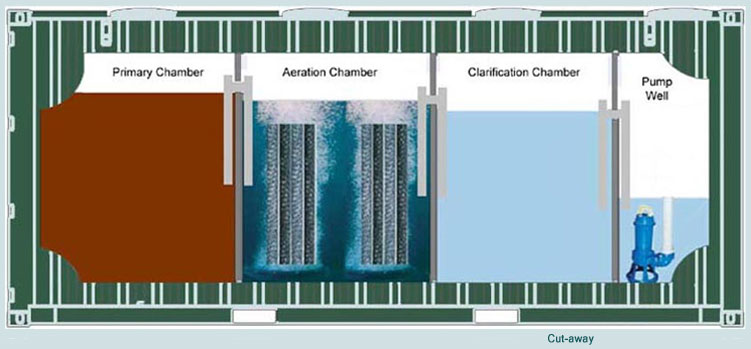

Transportable & Relocatable Wastewater Treatment Plants

A recent addition to OHW range of wastewater treatment options is

the engineer designed purpose built transportable & reusable STP.

Fully approved construction by Lloyds of London, these Plants are

housed in 20’ and 40’ containers to facilitate sea borne and road

transport options.

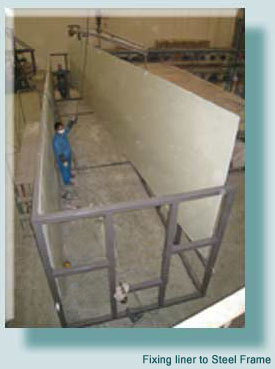

Each unit is ‘double skin’ constructed, comprising the container

walls to which is bonded a tubular steel reinforcing cage lined with

4mm fibreglass sheeting for watertight status and longevity.

All exposed metal surfaces are then sprayed with a corrosion protective

coating. Unique to this OHW design is the full use of the vessel’s

entire volume , which enables a gain in capacity & efficiency of up to 40%

over those plants of the “plastic tanks fitted into a container” variety. This advantage ultimately relates to a

smaller footprint and less transportation costs/litre of treatment capacity supplied.

Each unit is ‘double skin’ constructed, comprising the container

walls to which is bonded a tubular steel reinforcing cage lined with

4mm fibreglass sheeting for watertight status and longevity.

All exposed metal surfaces are then sprayed with a corrosion protective

coating. Unique to this OHW design is the full use of the vessel’s

entire volume , which enables a gain in capacity & efficiency of up to 40%

over those plants of the “plastic tanks fitted into a container” variety. This advantage ultimately relates to a

smaller footprint and less transportation costs/litre of treatment capacity supplied.

Treatment Capacities

The treatment capacity of the Plant will vary from project to project depending upon the constituent load contained

in the wastewater stream. Given that many mining and construction

applications are often located in areas with very high daily temperatures,

it is not uncommon to have a per capita water consumption of

300 litre in some instances. In other areas of a more temperate nature,

water consumption of 150 litres per capita is more the norm.

However, as a general rule, given a ‘domestic strength’ wastewater

quality, the following treatment capacities could be used as guidelines:-

20’ version …….. up to 10,000 litres/day or 50EP

40’ version ……...up to 20,000 litres/day or 100 EP

Combinations of multiple units to suit any flow volume Plants that

are required to treat very large volumes of influent could be coupled

with an up-front primary treatment tank fabricated from zincalume

or fiberglass for example, in order to lessen the overall cost. However,

this is only one of many mix and match options that are available

to create outcomes most suited to the purpose and the location.

Effluent Quality

The standard configuration of the transportable unit is designed to produce a B class effluent quality that in most instances will satisfy the on-site disposal requirements of the local and State authorities.

However, commissioning of the Plant with an

OHW staff member present is preferred where possible as on the spot training of the Customer’s representative can

take place. Once the project has been completed, the Plant can be quickly decommissioned either by OHW staff or

the Customer’s staff and is then ready to be collected and moved to the next project or placed in storage. Snap on/

snap off connections make commissioning and decommissioning the Plant a quick and simple task.

Residual effluent can be removed by tanker if available, and if not, the use of a ‘Geotube’ or similar is

recommended.

However, commissioning of the Plant with an

OHW staff member present is preferred where possible as on the spot training of the Customer’s representative can

take place. Once the project has been completed, the Plant can be quickly decommissioned either by OHW staff or

the Customer’s staff and is then ready to be collected and moved to the next project or placed in storage. Snap on/

snap off connections make commissioning and decommissioning the Plant a quick and simple task.

Residual effluent can be removed by tanker if available, and if not, the use of a ‘Geotube’ or similar is

recommended.